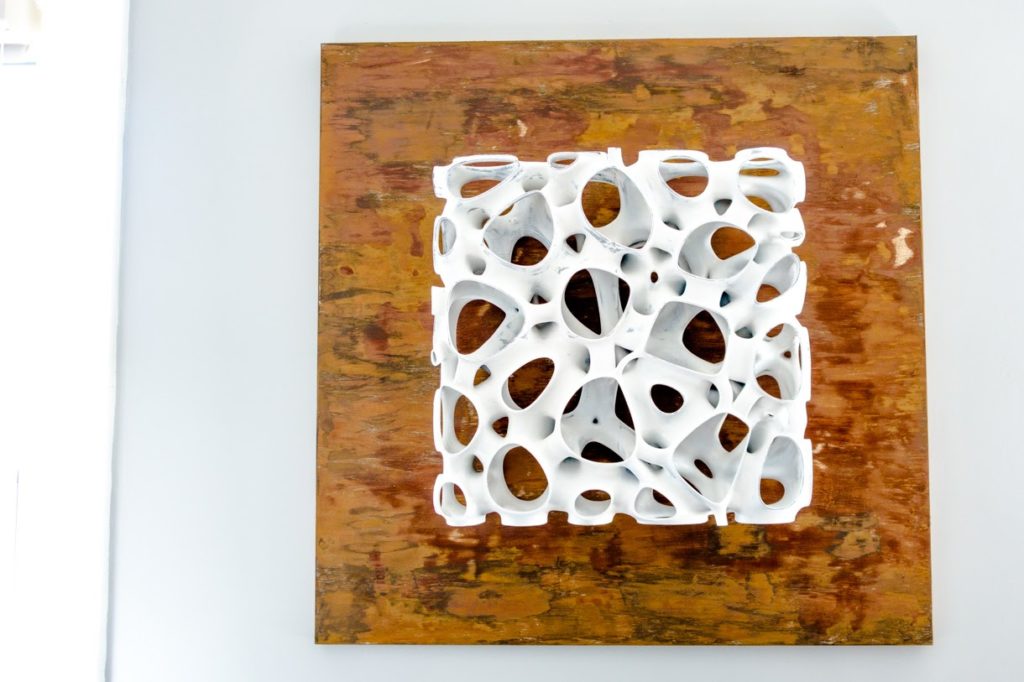

Medium: PLA Plastic, printed on Makerbot Replicator 2 in 8 parts.

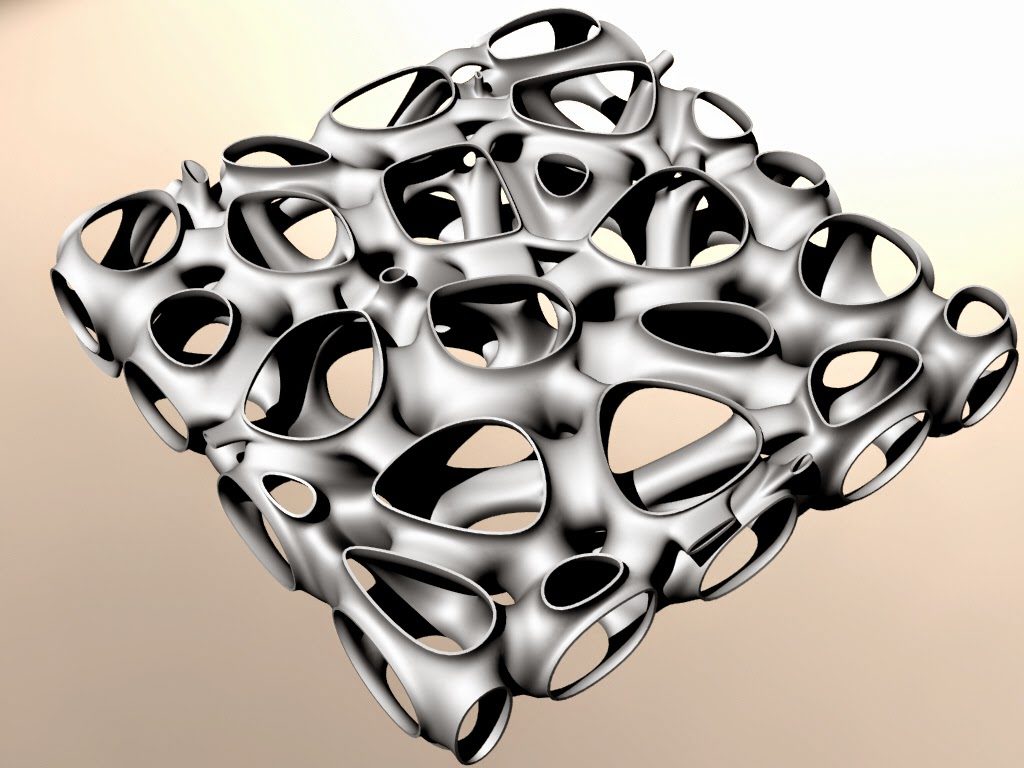

Modeled in Rhino3d with Grasshopper. Size of the veronoi part is 20″x20″. This was a super-challenging project to do with an FDM 3d printer, due to the large number of overhangs and small cavities. Each part took 10+ hours to print, but perhaps even more time to finish. I used a large amount of support material that was, at first a friend, then… a nightmare to extract and sand down.

Some learnings:

- If a space is too small to get your fingers into, it’s going to be a bear to sand. I took a few breaks from this project because finishing was so tedious.

- This project likely would have been much easier with access to a dual head printer with water-soluble filament or an SLA or SLS printer. When I started this in 2013, I didn’t have any access to such equipment and printing something this size with an online service would have been cost-prohibitive.

- Solvent glue works great with PLA.

- Makerware’s generated support is pretty good, but I could have saved myself a lot of time by modeling my own support for precarious overhangs and certain bridges. I had to throw away some prints and patch some gaps when Makerware’s support failed.